The Leader In 3D Printed Tooling Innovation

Tools In Half the Time & Half the Cost

Catalysis Is A Complete Solution Tool Maker That Uses 3D Printed Tooling

We are the leader in thermoforming tooling innovation. We are leading the charge of bringing additive manufacturing to the thermoforming industry. Our 3D printed tooling is manufactured for a fraction of the time and cost of traditional tooling, with much more durability and quality when compared to traditional tooling.

Vacuum Check

We always talk about how our tools are 100% porous and a part of our QC process is confirming vacuum function. Here’s a part of our test procedure testing the vacuum function of a 3D printed tool with no vacuum holes.

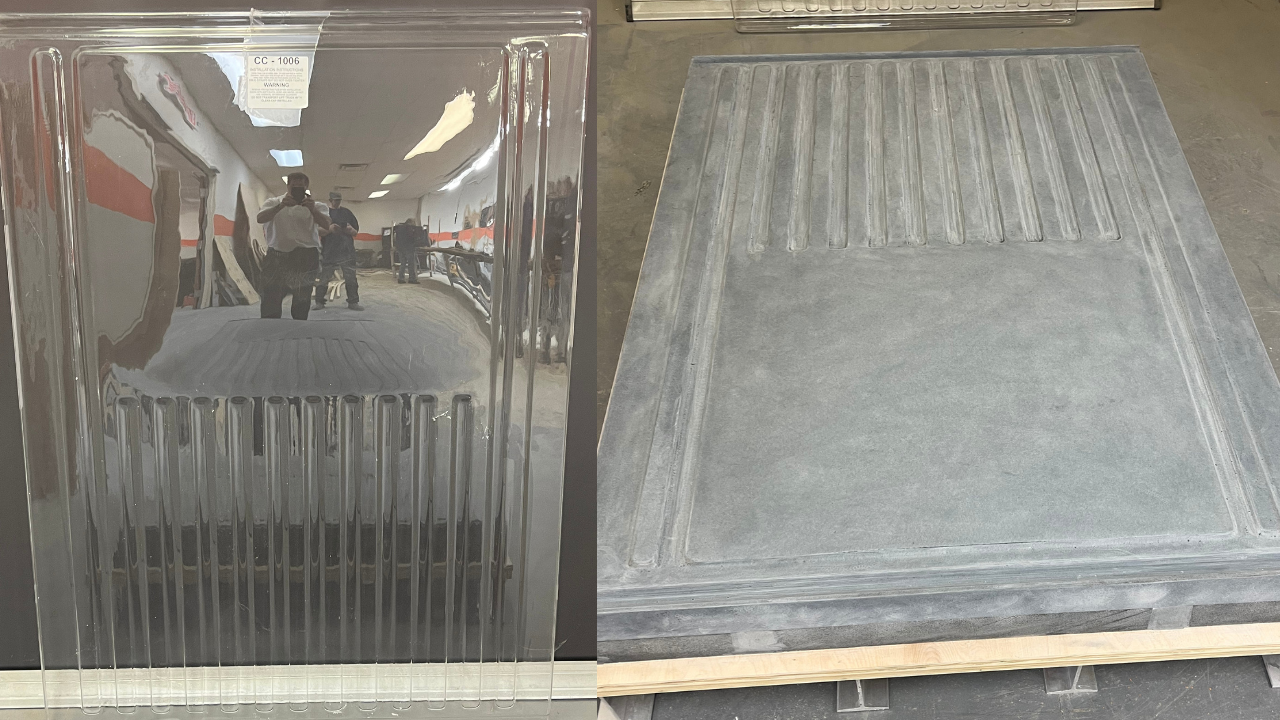

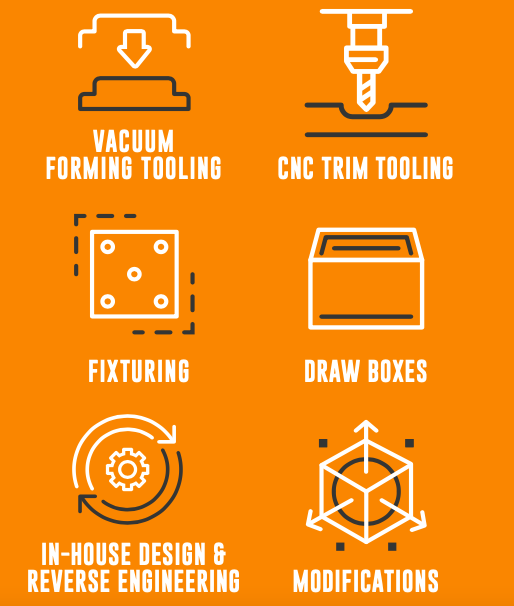

Vacuum Forming Tooling

The vacuum forming process involves heating a plastic sheet until it is soft and stretched onto a single surface mold. Where vacuum is applied to form the plastic over the mold surface to create the desired part.

Characteristics of a Catalysis 3D printed vacuum forming tool:

- 100% porous structure pulls a better quality part faster

- Made from a non-conductive material so no cooling is required

- Fully isotropic build avoids any delamination

- Light sand blast finish (100RA) eliminates A-side witness marks

- Highest production project ran 4,500 parts (.187″ ABS)

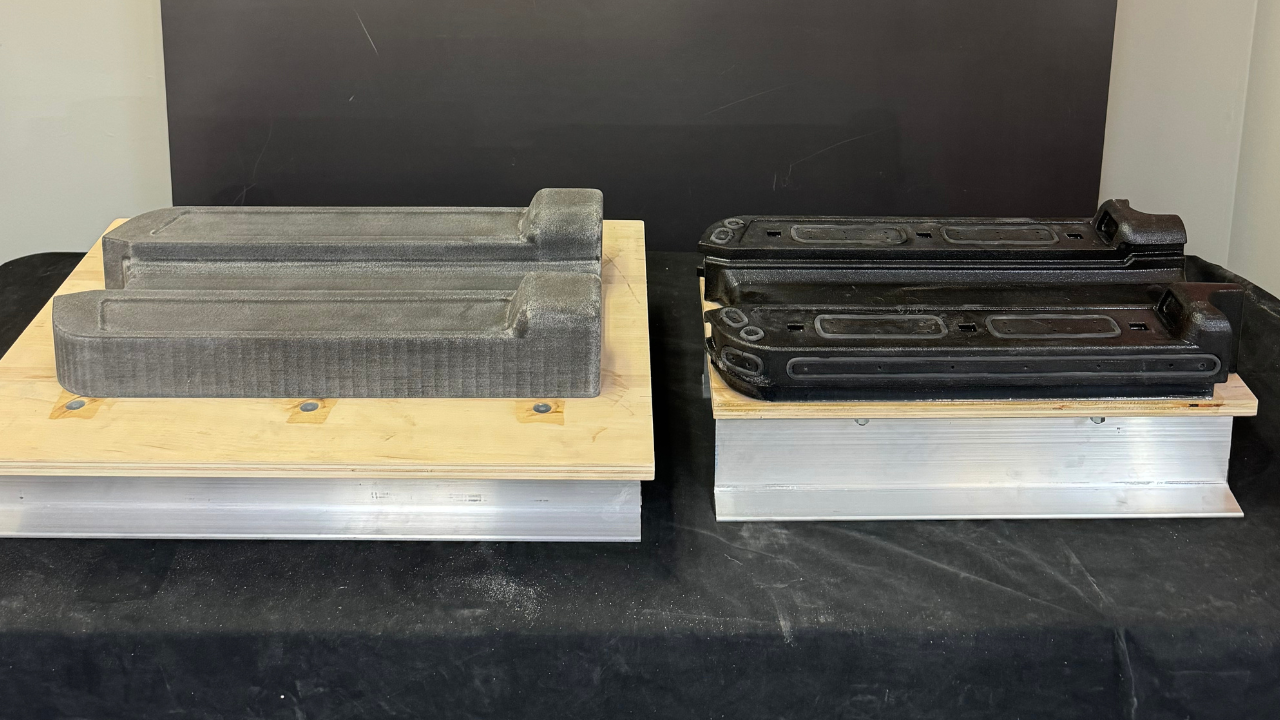

Twin Sheet Tooling

Twin sheet thermoforming is the process of vacuum forming 2 sheets of plastic together simultaneously. The process involves the use of two molds. Once formed, the top and bottom molds are brought together quickly, so as not to lose surface temperature.

Characteristics of a Catalysis 3D printed twin sheet tool:

- 100% porous structure pulls a better quality part faster

- Made from a non-conductive material so no cooling is required

- Fully isotropic build avoids any delamination

- Light sand blast finish (100RA) eliminates A-side witness marks)

Drape Forming Tooling

Drape forming is a process where a plastic sheet is heated then formed over a tool to make a part without the use of a vacuum. Our process allows us to get the tools printed, processed and to our customers as quickly as possible.

Characteristics of a Catalysis 3D printed drape forming tool:

- Fully isotropic build avoids any delamination

- Light sand blast finish (100RA) eliminates A-side witness marks

- Capable of high volume production

- Extremely fast print time allows us to get the tools printed, processed & to our customers as quickly as possible

Fixturing

A variety of fixtures can be made for CNC trimming, assembly, and part check purposes. The fixtures can accept and have rubber gaskets installed. In addition, the fixtures can be mounted to a box or mounting plate based on the customers needs. All fixtures use the same 3D printing technology, have the same design in order to save cost & time and are delivered together. Since all of the tools are made at the same time, this allows for an easier, more efficient time saving streamline process.

Fixtures Include:

- CNC Trim Fixtures

- QC Check Fixtures

- Assembly Fixtures

- Draw Boxes

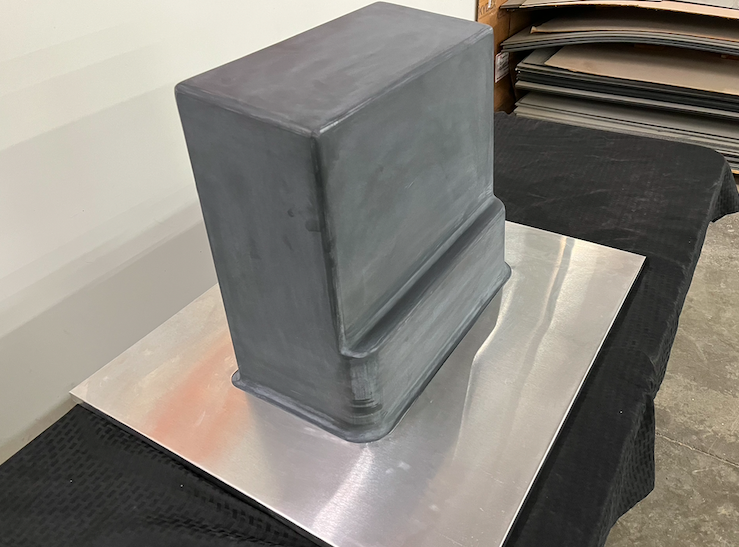

Foam Part Manufacturing Tooling

When it comes to foam part manufacturing tooling, we can either provide one tool for one part, or all tools needed for the entire vehicle in a manufacturing time of 3 weeks for prototype/low volume parts. Our 3D printed tooling technology enables tool designs that are not possible with traditional CNC manufacturing and has consistent thermal profiles by using integral copper water lines so each tool has the same thermal mass (similar shell thickness). Our 3D printed foam part manufacturing has a glossy tool surface finish, 85D scale hardness, strength required for 10-15 psi of foaming process, has a fully isotropic print structure and there is no delamination of the tool, meaning the tool will not separate (plastic tools will eventually separate).

Foam Part Manufacturing Tooling Applications include:

- Automotive Seating

- Airplane Seating

- Motorcycle Seating

Composite Part Manufacturing Tooling

Composite fabrication process involves a tool to shape the resin and reinforcement. A tool is required to give the resin/fiber combination its shape prior to enduring the curing process.

Characteristics of a Catalysis 3D printed composite part manufacturing tool:

- Fully isotropic build avoids any delamination

- Secondary coating gives a class A tool finish

- Capable of high volume production

- Extremely fast print time allows us to get the tools printed, processed & to our customers as quickly as possible

Our technology has allowed us to truly be a One-Stop-Shop for all of your tooling needs

Catalysis Additive Tooling was founded by utilizing a collective 60+ years of automotive engineering, tooling, and new model development experience. That experience combined with 10+ years of Additive Manufacturing/3D Printing research has allows us to develop the foundation of Catalysis and being able to offer our customers a complete solution to support their Development and Production needs.

FOUNDED ON EXPERIENCE

Companies We Do Business With

Our Latest News

3D Printed Thermoforming Tool For A Forklift Roof Cover

3D Printed Thermoforming Tool For A Forklift Roof Cover This large 39″ x 52″ tool is a 3D printed thermoforming tool to ...

2 Out 3D Printed Vacuum Forming Tool And 2 Out CNC Trim Tool

2 Out 3D Printed Vacuum Forming Tool And 2 Out CNC Trim Tool These tools are a 2 out 3D printed vacuum forming tool and a 2 out trim ...

Reverse Engineering Tools From a Fiberglass Part

Tool Time With Darrell Reverse Engineering Tools From A Fiberglass Part In this episode of ‘Tool Time With Darrell’, President & ...

Reverse Engineering From Old Wood Tools Using Laser Scanning

Reverse Engineering From Old Wood Tools We reverse engineered 3 3D printed vacuum forming tools from old wood tools that are at the ...

Complex 2 Out 3D Printed Thermoforming Tool

Complex 2 Out 3D Printed Thermoforming Tool This is a fully porous 2 out 3D printed thermoforming tool with a complex shape and a ...

3D Printed Foam Part Manufacturing Tooling

Tool Time With Darrell 3D Printed Foam Part Manufacturing Tooling In this episode of ‘Tool Time With Darrell’, President & CEO ...